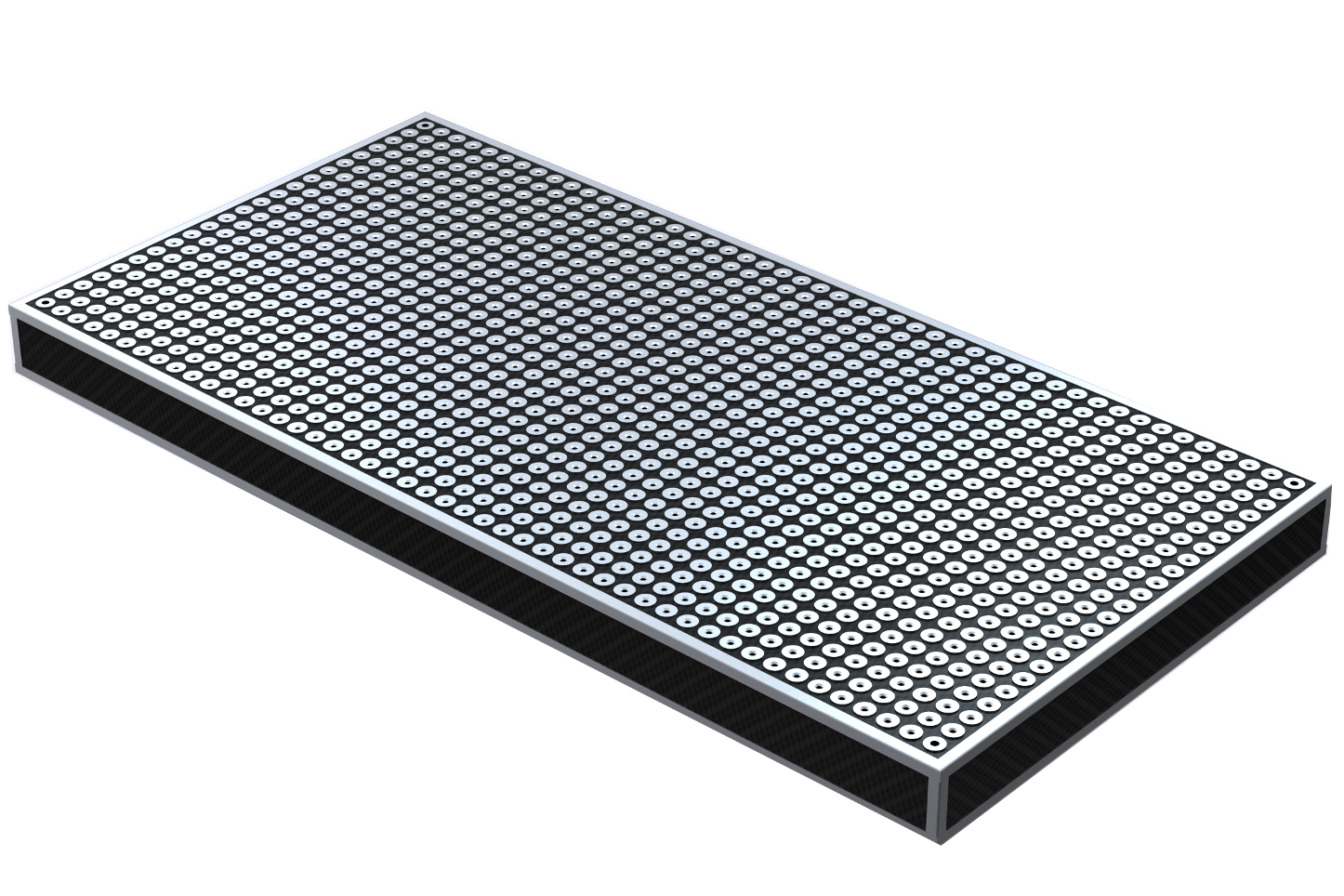

AD-Version

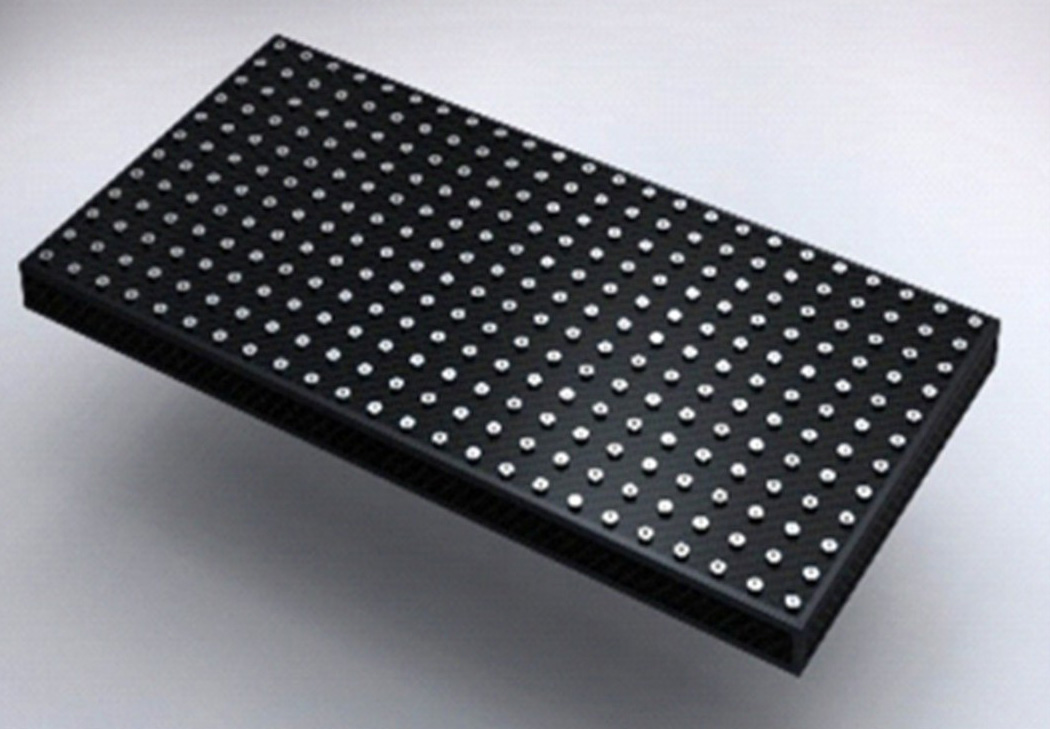

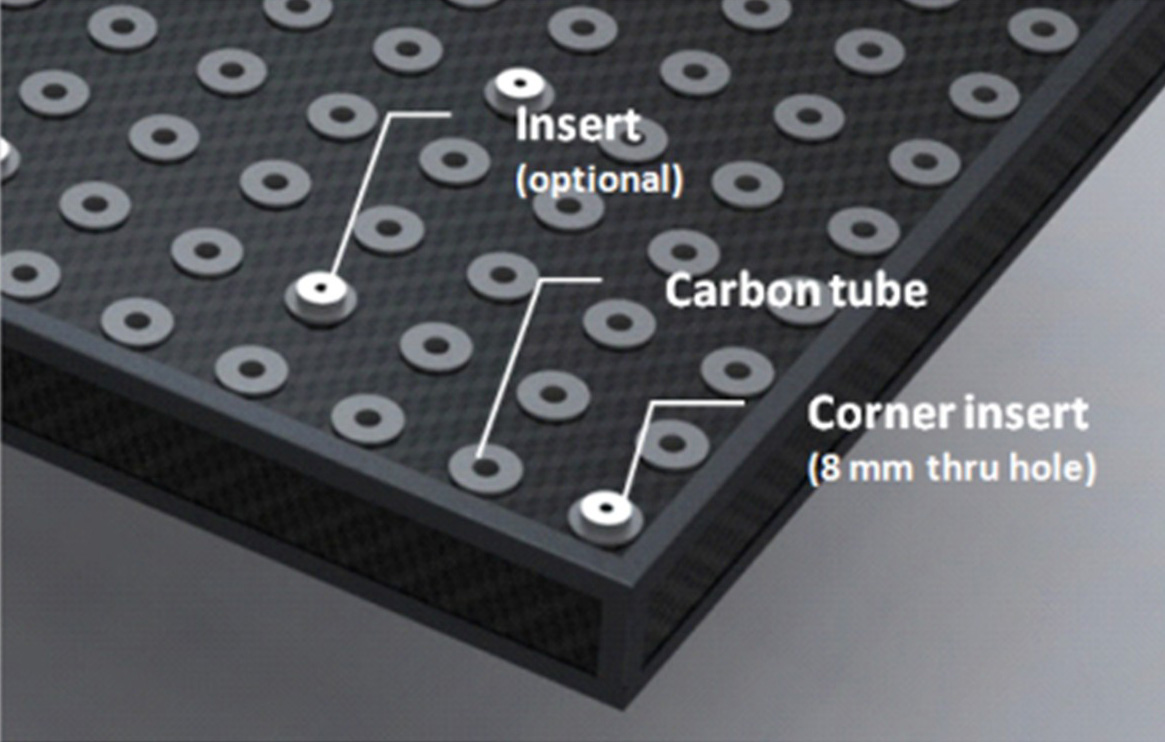

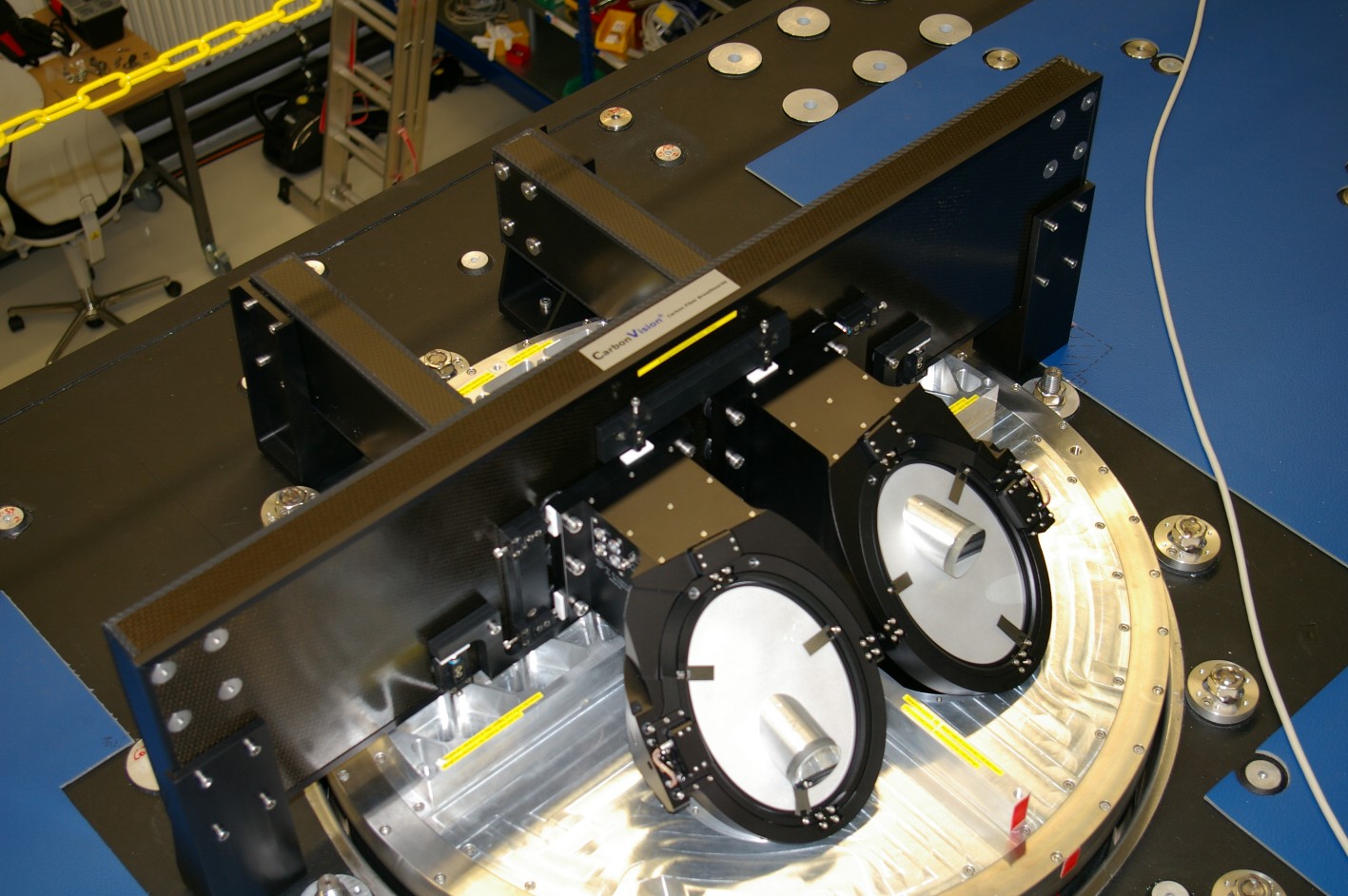

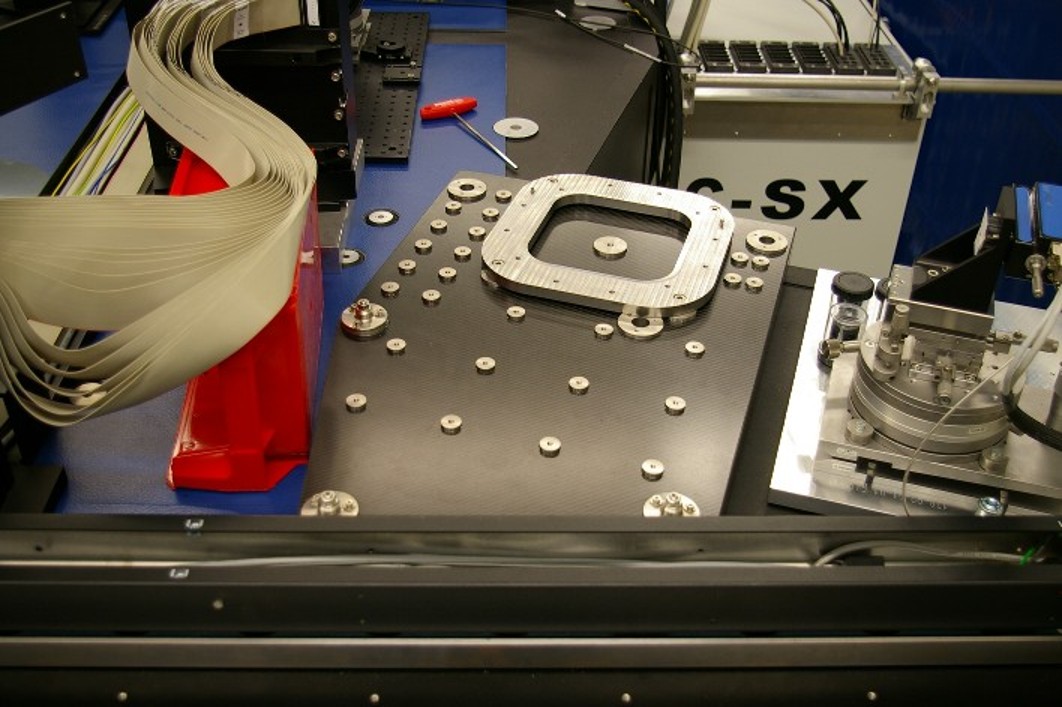

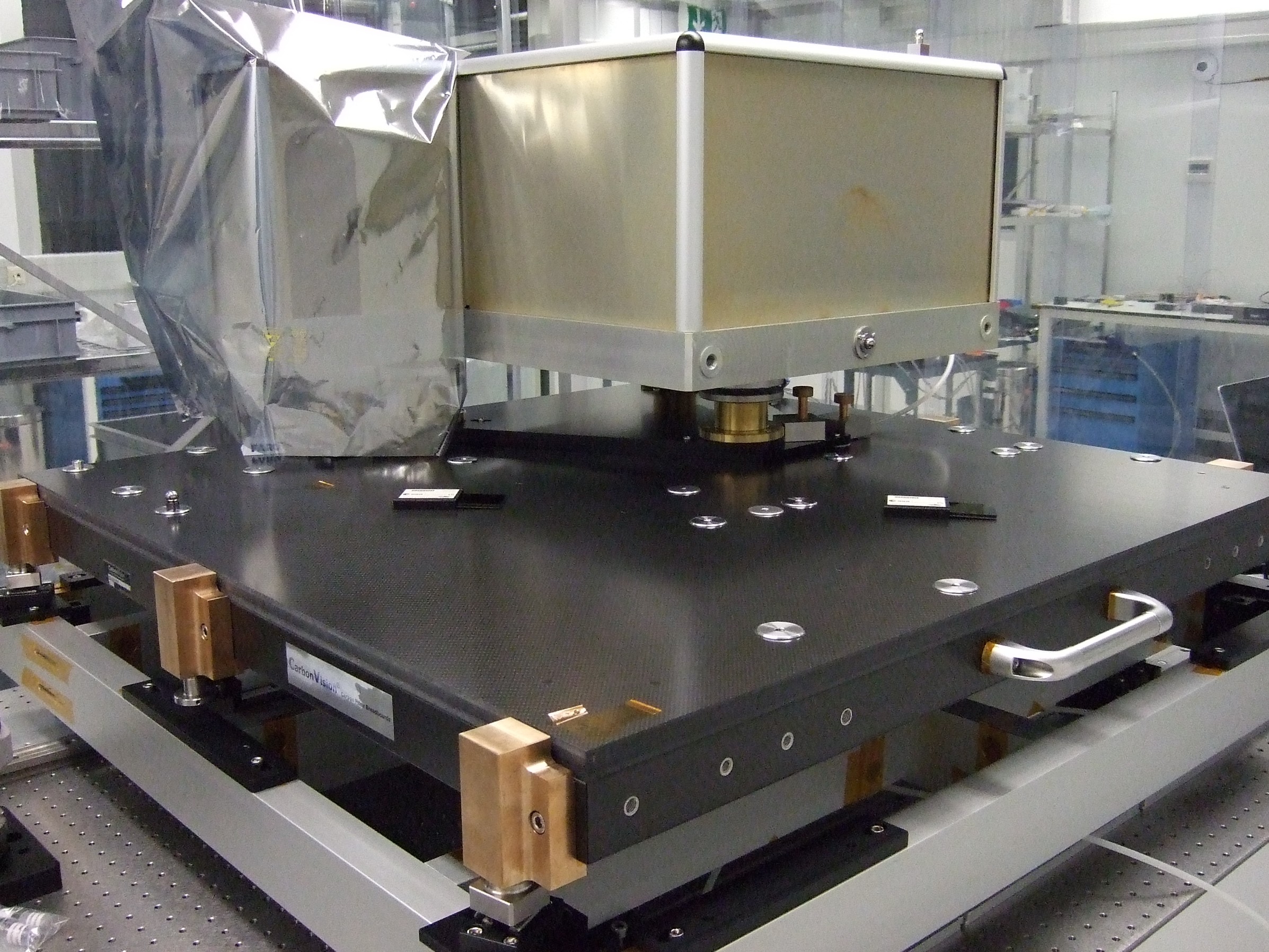

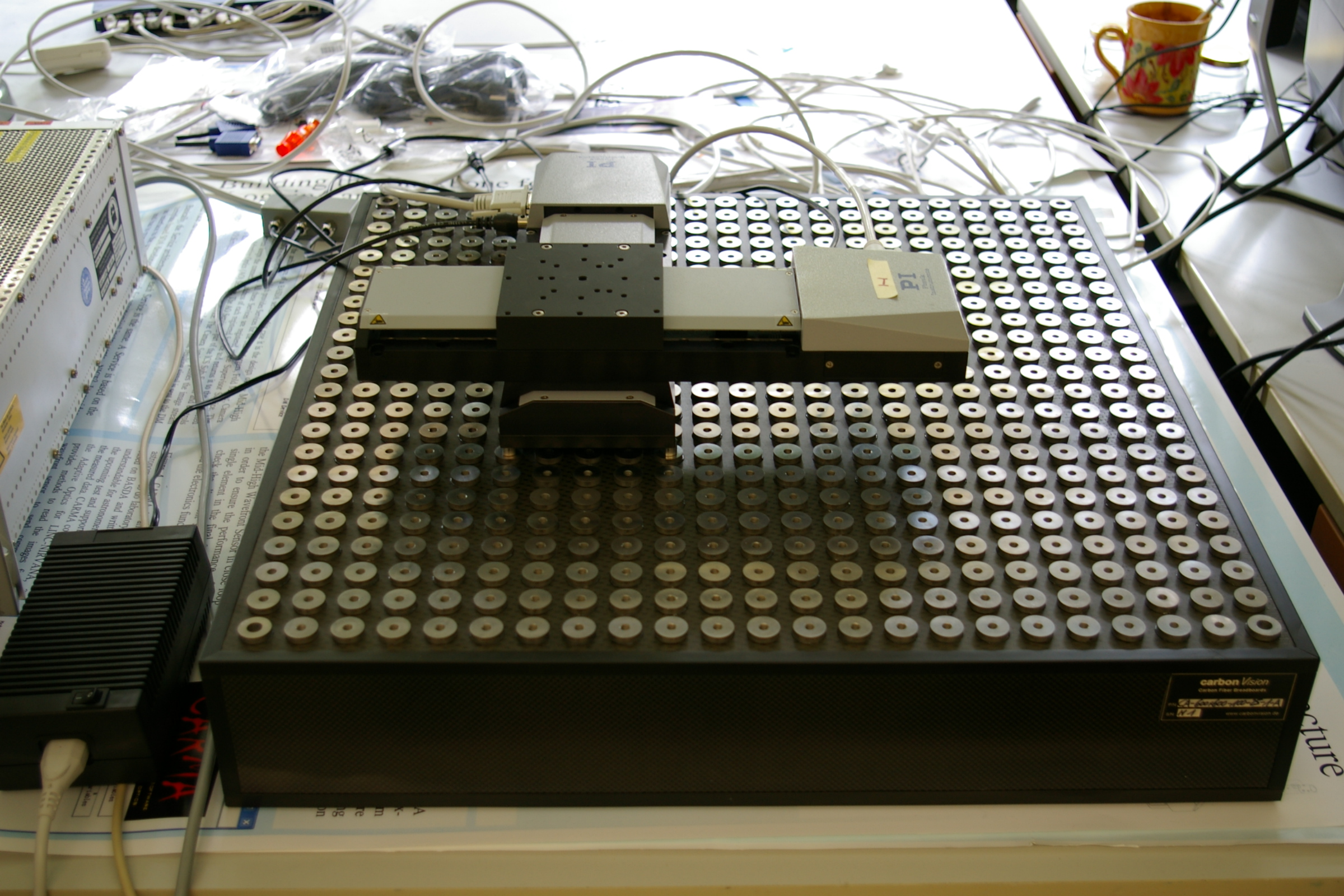

Advanced version of EC-series. At each mount location, a tube made from Carbon Fiber Reinforced Polymer (CFRP) links the top and bottom plate.

The tubes allow easy cleaning of the board, installation of removable additional mounts on the bottom side, tuning of natural frequencies and vibration damping by inserting adaptive elements.

Technical specifications

|

Dimension

|

Typical breadboard sizes are available, maximum size 2000 x 2500 mm

|

|

Thickness

|

Typical thickness ranges from 25, 50, 75 to 100 mm or according to structural requirements or customer needs

|

|

Flatness

|

Flatness of entire mounting surface AD- Version ≤ 0.05 mm , ADI- Version ≤ 0.2 mm

|

|

Mounting Grid

|

Typical mounting grid: 25×25 mm, 50×50 mm or customized

|

|

Mounting Holes

|

Metric and imperial threads, inserts are made from stainless steel, Aluminium, Titanium or INVAR

|

|

Damping

|

Nominal damping

|

|

Thermal Expansion

|

Lateral directions CTEx,y = 2.5 · 10 E-6 [mm/mm·K] @ 273 K for plane plate

|

|

Stiffness

|

Nominal stiffness

|

|

Weight

|

Area weight approximately 15 kg/m² (50 mm grid)

|

|

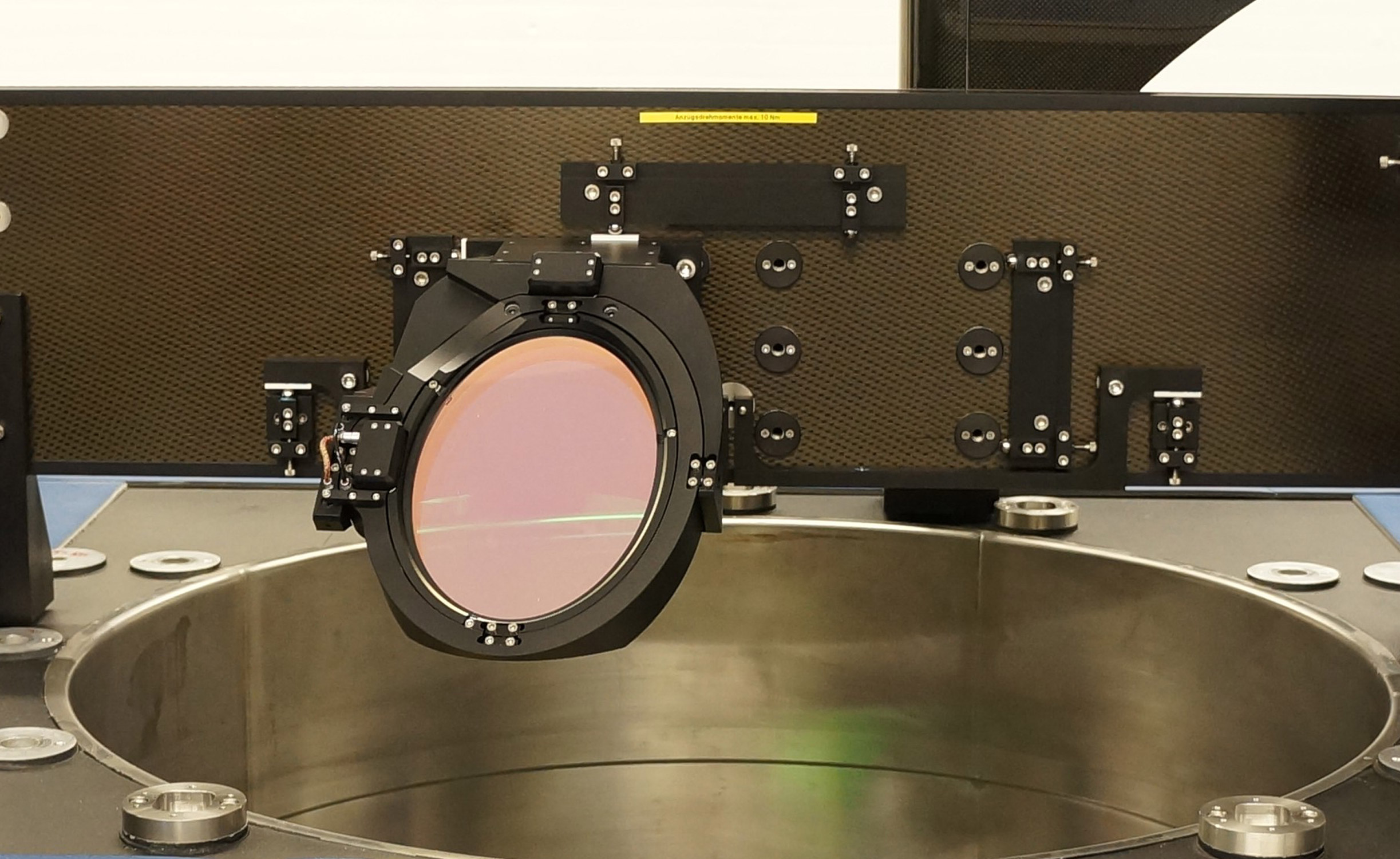

Design

|

– Honeycomb structure with skins made from multi-layered Carbon fiber fabrics cured with Epoxy Resin – Skins are designed typically to meet quasi-isotropic behaviour or according to structural/thermal requirements – High rigidity Aluminium or closed cell foam – CFRP tubes between upper and lower plate |

|

Top Side

|

Single inserts according mounting grid, with first inserts 25 mm from edges

|

|

Bottom Side

|

Single inserts with through hole at corners, 25 mm from edges or customized

|

|

Sidewalls

|

Carbon fiber plates with edge protection profiles

|

| Ventilation | For vacuum applications core materials are ventilated |

|

Cleanroom

|

Suitable

|